ATTIVITÀ

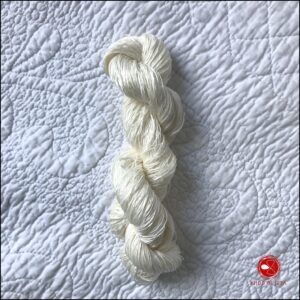

È la gelsibachicoltura l’attività principale. Seguiamo tutto il processo che parte dalla terra fino ad arrivare alla produzione del prezioso filato.

SERVIZI TURISTICI

All’interno del servizio turistico: fattoria didattica, servizio di ristorazione, escursioni eco esperienziali.

DICONO DI NOI

Sfoglia la nostra rassegna stampa. Scopri di più sul mondo di Nido di Seta. Una raccolta di articoli di stampa nazionale e internazionale.

Newsletter

Iscriviti alla nostra Newsletter per ricevere un buono sconto di 5€ per ordini superiori ai 79€ e per rimanere sempre aggiornato sulle iniziative di Nido di Seta.

CONTATTACI

GENTILE UTENTE, SE RISCONTRI PROBLEMI NELL’INVIO DELLA MAIL, TI PREGHIAMO DI COPIARE IL SEGUENTE INDIRIZZO info@nidodiseta.com ED INVIARCI LA MAIL DIRETTAMENTE DAL TUO DISPOSITIVO. STIAMO LAVORANDO ALLA RISOLUZIONE DEL PROBLEMA. GRAZIE

info@nidodiseta.com

+39 320 89 68 663

+39 347 24 72 207

Si riceve su appuntamento, Via Regina Elena, 88021 San Floro (CZ)